Tablet coating machines work on the principle of applying coating material as a solution to a group of tablets in a bed that can move horizontally or vertically. Tablet coating machine comes in different types and is used to coat the tablets with a thin layer of the coating material.

Tablets and capsules are solid dosage forms in which one or more drugs (API) and excipients are enclosed. The tablets are one of the most used and prescribed dosage forms since it has many advantages over other dosage forms it can available in different size, shape, color, weight, dissolution properties, and method of delivery.

Tablet coating in pharmaceutical manufacturing can serve several purposes. The main purpose of the tablet coating is to mask the unpleasant taste, odor, and color of the active pharmaceutical ingredients, make the tablet easier to swallow for the elder and children, to maintain the release profile of the tablets, although it is originally used to help maintain the integrity of the tablet.

A tablet coating machine is equipment that is commonly used in pharmaceutical industries for coats the outer surface of a tablet using a solution of the coating material. They are available in different types as per the application, desired coating process, and working principle.

Principle of the tablet coating machine:

A tablet coating equipment is very efficient in terms of coating the outside floor of a tablet using a unique thin film of the coating material. The basic principle of tablet coating is that the coating material in the form of solution is applied to a moving bed of the tablet. The tablets to be coated are placed in a closed drum and rotated in an orbital manner by impact from a streamlined plate. The coating material is sprayed automatically on the tablets during this orbital motion which avoids an additional coating. It also uses hot air to remove solvents and maintains the dryness of the tablet.

Different types of tablet coating equipment:

Depending on the working principle, there are three types of machines are used in the tablet coating.

1. Standard coating pan

2. Perforated coating pan

3. Fluidized-bed coater

Standard coating pan:

The standard coating pan is a circular metal pan positioned at 40 degrees, 8-60 inches in diameter, and angularly placed on a stand rotated by the motor on its horizontal axis. Heated air is directed to the tablet bed surface in the pan and is exhausted through ducts. The coating solution is sprayed to tablets by spraying or lading.

Perforated coating pan:

The perforated coating pan is fully perforated and it includes mixing blades. The inlet air is in contact with the top of the pan by a plenum. The plenum at the bottom of the pan dissipates the air.

Fluidized bed coater:

Fluid bed coaters are types of tablet coating equipment which are used in fluid materials by fluid bed technology. By this technology the particles are fluidized and the coating liquid is sprayed on the dried material. The low viscosity and small droplets of the spray medium make the sure uniform coating of the pharmaceutical product. The basic principle involved in this process can be either the bottom spray or the top spray or the tangent spray method.

Commonly asked questions on dosage forms are as follows.

What are the types of tablet coating?

There are several types of tablet coating such as sugar coating, enteric-coating, film-coating, compression coating, and electrostatic dry coating, etc.

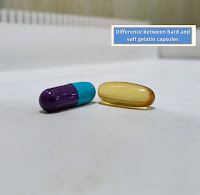

What is the difference between hard and soft gelatin capsules?

The difference between hard and soft gelatin capsules is that hard gelatin capsules are used for solids, while soft gelatin capsules are used for liquid or semi-solid substances.

Why are tablets coated?

The coating is designed to mask the unpleasant taste, and odor of the drug, and it’s also designed to maintain the tablet collectively in the stomach and release it in the intestine.

What are the steps involved in tablet coating?

Batch identification and selection of recipe, loading or dispensing, warming, spraying, drying, cooling, and unloading are the processes that are involved in the coating.

You may also like this